| Several examples of our automatic test equipment expertise can be found below by clicking on each description in the table. For more information on a custom automated system design for your application, a fixed price quote, or time and materials rates. Contact us now by calling 1-734-455-1311 or filling out the short form on the right of the page. |

|

|

Industries of Application:

1 Automotive 2 Aerospace 3 Military 4 Medical

|

|

|

The system tests 24 Automotive Instrument Clusters at one time. The durability system consists of four equipment racks and one environmental test chamber. Each of the four racks controls and monitors six instrument clusters at a time. The system is designed to fully simulate automotive CAN communication protocol on each of the 24 parts under test while continuously monitoring the parts for abnormal behavior. To maintain test process synchronization, one of the four racks controls the test sequencing and controls the temperature profile of the environmental chamber. The system tests 24 Automotive Instrument Clusters at one time. The durability system consists of four equipment racks and one environmental test chamber. Each of the four racks controls and monitors six instrument clusters at a time. The system is designed to fully simulate automotive CAN communication protocol on each of the 24 parts under test while continuously monitoring the parts for abnormal behavior. To maintain test process synchronization, one of the four racks controls the test sequencing and controls the temperature profile of the environmental chamber. |

|

High volume production of Remote Keyless Entry (RKE) modules requires mechanical button actuation while performing sophisticated RF and LF testing. The palletized conveyor system shown is designed to perform relative RF power measurements, RF carrier frequency measurements, decode the encrypted RF message and program test data in an LF RFID chip embedded in the modules under test. One operator loads and unloads the test system. If the parts pass all tests they are marked with an FCC identification number and returned to the load station. If the parts fail, they are sent to a retention area (right end of the machine) where the parts must be removed before the empty pallet is returned to the main conveyor track. Takt time is less than 10 seconds for two parts. High volume production of Remote Keyless Entry (RKE) modules requires mechanical button actuation while performing sophisticated RF and LF testing. The palletized conveyor system shown is designed to perform relative RF power measurements, RF carrier frequency measurements, decode the encrypted RF message and program test data in an LF RFID chip embedded in the modules under test. One operator loads and unloads the test system. If the parts pass all tests they are marked with an FCC identification number and returned to the load station. If the parts fail, they are sent to a retention area (right end of the machine) where the parts must be removed before the empty pallet is returned to the main conveyor track. Takt time is less than 10 seconds for two parts.

|

|

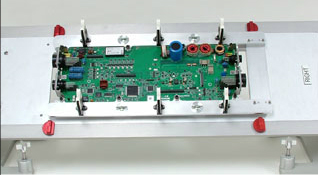

.jpg) Fully assembled PCBAs often require specialized fixturing to perform End of Line (EOL) function performance tests. The test fixture shown below is part of a conveyor system and is designed to probe the bottom of the PCBA using conventional pogo pin probes while at the same time providing 12 specialized light compartments on the top of the PCBA. The fixture is shown open in Figure 1 and Figure 2 shows the PCBA positioned over the pogo pins on conveyor tracks. The fixture was designed to lift the PCBA from the conveyor, maintain a +/- probing the bottom of the PCBA while providing 12 light chambers down on the top of the PCBA. Fully assembled PCBAs often require specialized fixturing to perform End of Line (EOL) function performance tests. The test fixture shown below is part of a conveyor system and is designed to probe the bottom of the PCBA using conventional pogo pin probes while at the same time providing 12 specialized light compartments on the top of the PCBA. The fixture is shown open in Figure 1 and Figure 2 shows the PCBA positioned over the pogo pins on conveyor tracks. The fixture was designed to lift the PCBA from the conveyor, maintain a +/- probing the bottom of the PCBA while providing 12 light chambers down on the top of the PCBA.

1.jpg)

|

|

Often it is necessary to test electrical components after they have been delivered to the OEM. These components are frequently part of a complex system and cannot be made to function unless they are controlled and powered as if connected to the entire system. In the example below, it was necessary to test the LED indicator functions, test the pushbutton switch, run the part at specific voltages from 6 to 16 volts, verify the LIN communications protocol and measure current consumption. FEI developed a portable test sytem to satisfy the test requirements. Often it is necessary to test electrical components after they have been delivered to the OEM. These components are frequently part of a complex system and cannot be made to function unless they are controlled and powered as if connected to the entire system. In the example below, it was necessary to test the LED indicator functions, test the pushbutton switch, run the part at specific voltages from 6 to 16 volts, verify the LIN communications protocol and measure current consumption. FEI developed a portable test sytem to satisfy the test requirements. |

|

Camera based inspection systems can be used to evaluate the operational performance of components over extreme temperature ranges. In the example below, commercially available video inspection cameras were used to verify the accuracy and performance of automotive instrument panels (IP). The cameras were mounted in self contained environmental enclosures and low pressure nitrogen was supplied to each camera to keep the camera within its safe operating temperature and assure that the quartz window in front of each camera lens remained free of condensation during rapid temperature transitions. The cameras were mounted on a computer controlled rotary pedestal to allow the cameras to look at any one of the six IPs located on the fixture. Camera based inspection systems can be used to evaluate the operational performance of components over extreme temperature ranges. In the example below, commercially available video inspection cameras were used to verify the accuracy and performance of automotive instrument panels (IP). The cameras were mounted in self contained environmental enclosures and low pressure nitrogen was supplied to each camera to keep the camera within its safe operating temperature and assure that the quartz window in front of each camera lens remained free of condensation during rapid temperature transitions. The cameras were mounted on a computer controlled rotary pedestal to allow the cameras to look at any one of the six IPs located on the fixture.

|

|

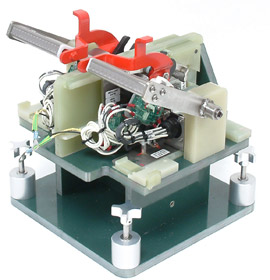

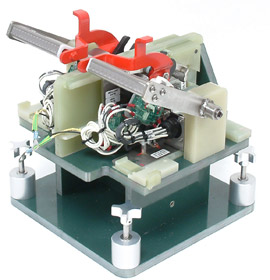

Electro mechanical testing frequently requires a mechanical stimulus coupled with electrical measurements of the product. In the example shown, emergency release levers (shown in red) for the passenger doors on mass transit vehicles needed to be evaluated. The effort required to actuate the release lever was measured with a torque transducer and the proper sequencing of the electrical switches and latch solenoid operation was verified using an automatic electronic test system. Electro mechanical testing frequently requires a mechanical stimulus coupled with electrical measurements of the product. In the example shown, emergency release levers (shown in red) for the passenger doors on mass transit vehicles needed to be evaluated. The effort required to actuate the release lever was measured with a torque transducer and the proper sequencing of the electrical switches and latch solenoid operation was verified using an automatic electronic test system.

|

|

Small compact automated test systems can be used for product development, design validation and low volume production testing of a wide variety of electronic and electro mechanical parts. The systems shown below perform optical inspection, final performance validation on circuit board assemblies (left) and completely assembled components (right). Software and electrical interface wiring change to accommodate hardware specific connections, but both systems use the same automatic test equipment. |

|

It is frequently necessary to mechanically manipulate devices under test (DUT). The test may require that complex motions be applied to the DUT. Shown below is a robotically actuated test system that is used to simulate driver actuation of multifunction turn signal switches used in Class 7 and 8 heavy duty trucks. This automated test system continuously monitors and logs the efforts necessary to activate all functions and validates switch operation during motion. It is frequently necessary to mechanically manipulate devices under test (DUT). The test may require that complex motions be applied to the DUT. Shown below is a robotically actuated test system that is used to simulate driver actuation of multifunction turn signal switches used in Class 7 and 8 heavy duty trucks. This automated test system continuously monitors and logs the efforts necessary to activate all functions and validates switch operation during motion.

|

|

In the example below, it was necessary to calibrate and linearize the electrical output of a differential pressure transducer used to control a sleep apnea machine. The critical part of the machine involved connecting the integrated circuit (IC) to a differential pressure source while establishing electrical connection to the IC for flash programming of the IC with quadratic linearization coefficients. Measurement accuracy requirements dictated the use of stainless steel hard piping to specially designed low leak rate pneumatic port couplers. The two differential pneumatic ports are molded into the plastic housing of the IC. In the example below, it was necessary to calibrate and linearize the electrical output of a differential pressure transducer used to control a sleep apnea machine. The critical part of the machine involved connecting the integrated circuit (IC) to a differential pressure source while establishing electrical connection to the IC for flash programming of the IC with quadratic linearization coefficients. Measurement accuracy requirements dictated the use of stainless steel hard piping to specially designed low leak rate pneumatic port couplers. The two differential pneumatic ports are molded into the plastic housing of the IC.

|

The system tests 24 Automotive Instrument Clusters at one time. The durability system consists of four equipment racks and one environmental test chamber. Each of the four racks controls and monitors six instrument clusters at a time. The system is designed to fully simulate automotive CAN communication protocol on each of the 24 parts under test while continuously monitoring the parts for abnormal behavior. To maintain test process synchronization, one of the four racks controls the test sequencing and controls the temperature profile of the environmental chamber.

The system tests 24 Automotive Instrument Clusters at one time. The durability system consists of four equipment racks and one environmental test chamber. Each of the four racks controls and monitors six instrument clusters at a time. The system is designed to fully simulate automotive CAN communication protocol on each of the 24 parts under test while continuously monitoring the parts for abnormal behavior. To maintain test process synchronization, one of the four racks controls the test sequencing and controls the temperature profile of the environmental chamber. High volume production of Remote Keyless Entry (RKE) modules requires mechanical button actuation while performing sophisticated RF and LF testing. The palletized conveyor system shown is designed to perform relative RF power measurements, RF carrier frequency measurements, decode the encrypted RF message and program test data in an LF RFID chip embedded in the modules under test. One operator loads and unloads the test system. If the parts pass all tests they are marked with an FCC identification number and returned to the load station. If the parts fail, they are sent to a retention area (right end of the machine) where the parts must be removed before the empty pallet is returned to the main conveyor track. Takt time is less than 10 seconds for two parts.

High volume production of Remote Keyless Entry (RKE) modules requires mechanical button actuation while performing sophisticated RF and LF testing. The palletized conveyor system shown is designed to perform relative RF power measurements, RF carrier frequency measurements, decode the encrypted RF message and program test data in an LF RFID chip embedded in the modules under test. One operator loads and unloads the test system. If the parts pass all tests they are marked with an FCC identification number and returned to the load station. If the parts fail, they are sent to a retention area (right end of the machine) where the parts must be removed before the empty pallet is returned to the main conveyor track. Takt time is less than 10 seconds for two parts..jpg) Fully assembled PCBAs often require specialized fixturing to perform End of Line (EOL) function performance tests. The test fixture shown below is part of a conveyor system and is designed to probe the bottom of the PCBA using conventional pogo pin probes while at the same time providing 12 specialized light compartments on the top of the PCBA. The fixture is shown open in Figure 1 and Figure 2 shows the PCBA positioned over the pogo pins on conveyor tracks. The fixture was designed to lift the PCBA from the conveyor, maintain a +/- probing the bottom of the PCBA while providing 12 light chambers down on the top of the PCBA.

Fully assembled PCBAs often require specialized fixturing to perform End of Line (EOL) function performance tests. The test fixture shown below is part of a conveyor system and is designed to probe the bottom of the PCBA using conventional pogo pin probes while at the same time providing 12 specialized light compartments on the top of the PCBA. The fixture is shown open in Figure 1 and Figure 2 shows the PCBA positioned over the pogo pins on conveyor tracks. The fixture was designed to lift the PCBA from the conveyor, maintain a +/- probing the bottom of the PCBA while providing 12 light chambers down on the top of the PCBA.

1.jpg)

Often it is necessary to test electrical components after they have been delivered to the OEM. These components are frequently part of a complex system and cannot be made to function unless they are controlled and powered as if connected to the entire system. In the example below, it was necessary to test the LED indicator functions, test the pushbutton switch, run the part at specific voltages from 6 to 16 volts, verify the LIN communications protocol and measure current consumption. FEI developed a portable test sytem to satisfy the test requirements.

Often it is necessary to test electrical components after they have been delivered to the OEM. These components are frequently part of a complex system and cannot be made to function unless they are controlled and powered as if connected to the entire system. In the example below, it was necessary to test the LED indicator functions, test the pushbutton switch, run the part at specific voltages from 6 to 16 volts, verify the LIN communications protocol and measure current consumption. FEI developed a portable test sytem to satisfy the test requirements. Camera based inspection systems can be used to evaluate the operational performance of components over extreme temperature ranges. In the example below, commercially available video inspection cameras were used to verify the accuracy and performance of automotive instrument panels (IP). The cameras were mounted in self contained environmental enclosures and low pressure nitrogen was supplied to each camera to keep the camera within its safe operating temperature and assure that the quartz window in front of each camera lens remained free of condensation during rapid temperature transitions. The cameras were mounted on a computer controlled rotary pedestal to allow the cameras to look at any one of the six IPs located on the fixture.

Camera based inspection systems can be used to evaluate the operational performance of components over extreme temperature ranges. In the example below, commercially available video inspection cameras were used to verify the accuracy and performance of automotive instrument panels (IP). The cameras were mounted in self contained environmental enclosures and low pressure nitrogen was supplied to each camera to keep the camera within its safe operating temperature and assure that the quartz window in front of each camera lens remained free of condensation during rapid temperature transitions. The cameras were mounted on a computer controlled rotary pedestal to allow the cameras to look at any one of the six IPs located on the fixture. Electro mechanical testing frequently requires a mechanical stimulus coupled with electrical measurements of the product. In the example shown, emergency release levers (shown in red) for the passenger doors on mass transit vehicles needed to be evaluated. The effort required to actuate the release lever was measured with a torque transducer and the proper sequencing of the electrical switches and latch solenoid operation was verified using an automatic electronic test system.

Electro mechanical testing frequently requires a mechanical stimulus coupled with electrical measurements of the product. In the example shown, emergency release levers (shown in red) for the passenger doors on mass transit vehicles needed to be evaluated. The effort required to actuate the release lever was measured with a torque transducer and the proper sequencing of the electrical switches and latch solenoid operation was verified using an automatic electronic test system.

It is frequently necessary to mechanically manipulate devices under test (DUT). The test may require that complex motions be applied to the DUT. Shown below is a robotically actuated test system that is used to simulate driver actuation of multifunction turn signal switches used in Class 7 and 8 heavy duty trucks. This automated test system continuously monitors and logs the efforts necessary to activate all functions and validates switch operation during motion.

It is frequently necessary to mechanically manipulate devices under test (DUT). The test may require that complex motions be applied to the DUT. Shown below is a robotically actuated test system that is used to simulate driver actuation of multifunction turn signal switches used in Class 7 and 8 heavy duty trucks. This automated test system continuously monitors and logs the efforts necessary to activate all functions and validates switch operation during motion. In the example below, it was necessary to calibrate and linearize the electrical output of a differential pressure transducer used to control a sleep apnea machine. The critical part of the machine involved connecting the integrated circuit (IC) to a differential pressure source while establishing electrical connection to the IC for flash programming of the IC with quadratic linearization coefficients. Measurement accuracy requirements dictated the use of stainless steel hard piping to specially designed low leak rate pneumatic port couplers. The two differential pneumatic ports are molded into the plastic housing of the IC.

In the example below, it was necessary to calibrate and linearize the electrical output of a differential pressure transducer used to control a sleep apnea machine. The critical part of the machine involved connecting the integrated circuit (IC) to a differential pressure source while establishing electrical connection to the IC for flash programming of the IC with quadratic linearization coefficients. Measurement accuracy requirements dictated the use of stainless steel hard piping to specially designed low leak rate pneumatic port couplers. The two differential pneumatic ports are molded into the plastic housing of the IC.